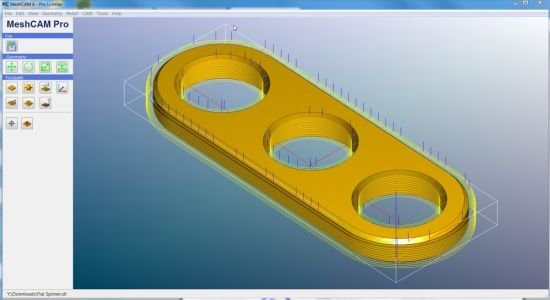

MeshCam Pro v8.43 Build 43 (x64) | 27 MB | Language: English

MeshCAM is the fastest way to generate gcode. You have a simple goal, to take a CAD file and get your mill to cut it. You do not want to become an expert on CAM software, you want parts today. MeshCAM is made for people who just want to make parts now.

MeshCAM works with your CAD:

MeshCAM works with almost every 3D CAD program by opening the two most common 3D file formats, STL and DXF.

If you just want to make 2D parts without using a 3D CAD program, you can load 2D DXF files (in R12 format) and extrude them to a 3D part.

We have got lots of users of:

Alibre

Solidworks

Autodesk Inventor

OnShape

Rhino 3D

SketchUp

Viacad

Autocad

Freecad

OpenSCAD

Tinkercad

Blender

ZBrush

And many many more…

No CAD- No Problem

Sometimes you need a part that cannot be designed with a traditional CAD program.

Sometimes you do not even have a CAD program.

If this sounds like you, do not worry. You can open any image file (JPG, BMP, or PNG) in MeshCAM and the image will be converted to a 3D surface that can be machined directly.

Users have come up with incredible uses for this feature to make parts that would be almost impossible with a traditional CAD program.

Works with your CNC machine:

MeshCAM has a built-in post processor to transform the gcode to work with your machine. It supports lots of machine types as-is and it can be extended to support most other

No machining knowledge required

The worst part of any new CNC software is being confronted by a wall of settings to create a toolpath.

Stepover, stepdown, waterline, threshold angles Do you want to learn a whole new language just to get your first toolpath?

MeshCAM has an Automatic Toolpath Wizard that picks as many of those values as possible so that you do not have to.

You just pick the cutters, tell MeshCAM the desired quality level, and it will analyze the model to pick values to get you started. You can tweak them to make them better or use them as-is.

If you already know what you are doing then do not worry- you still have complete control over all of your toolpath settings.

Machine almost anything

Every part requires a slightly different approach to machine it efficiently. If your CAM software does not give you enough toolpath strategies then you will spend more time to machine your part or you will give up finish quality. This is not something you have to worry about with MeshCAM.

MeshCAM has more toolpath options than any competing CAM program.

Parallel Roughing (2D and 3D)

Contour Offset Roughing (2D and 3D)

Parallel Finishing

Waterline Finishing

Pencil Finishing

This combination of toolpaths will machine almost any part you can imagine.

Eliminate complicated fixtures

Some parts are very difficult to machine because they’re very difficult to hold down. Clamps and vises get in the way and turn what should be an easy job into a complicated one.

MeshCAM lets you add supports/tabs to your part so that it remains connected to the stock during machining. The supports hold the part in place so you can keep the cutter away from your vise.

MeshCAM does this without help from your CAD program so it doesn’t depend on anything but MeshCAM itself.

Machine HUGE parts

MeshCAM was designed from the start to support HUGE 3D files. Huge in physical size and huge in file size.

Users are making boats and large museum exhibits in MeshCAM using large CNC routers.

Jewelers and engineers are making incredibly detailed parts with files that contain millions of polygons.

See what your part will look like when it’s done (PRO Version)

MeshCAM Pro includes a 3D toolpath simulator that will show you not only where the tool will go, but how the finished part will look.

Sometimes you don’t have time to run a toolpath to see how it will turn out, or you can just use simulation to try different settings to see how the part changes.

This is the absolute fastest way to see what your parts will look like with no wasted time, cutters, or stock.

Homepage: https://www.abelssoft.de